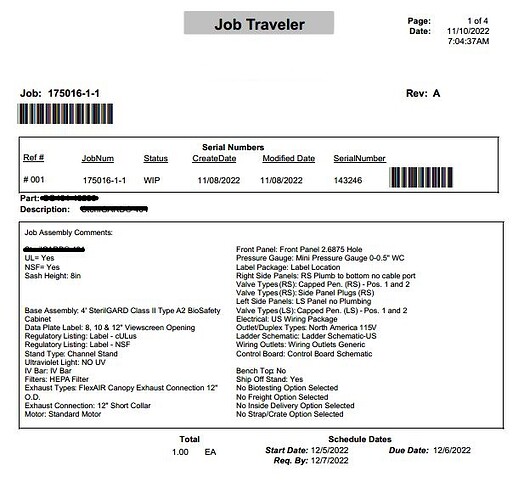

We are currently looking to change the way we handle Jobs and the paperwork (Traveler) that goes with it. I have attached an image of our current traveler. When we brought in Epicor, It was never fully setup and the work that was done was to mimic how the previous MRP operated. I do not know if this is standard however you can see we have a comments section directly under the Job# and Serial# section. In this section we list what options this job has. the majority of our work is custom in the sense of configurated. the works finds this comment section to be hard to read. Most all workers knows what piece parts would be needed for each configuration. So here we would like to give a list of configurations/options of only what is un this unit. Basically a single level BOM would work I think. Most of the options are phantom assemblies.

I would like to know if there is a way to automate this information that shows up in the section.

The next sheet would be the operations. Our thinking is the operations would list out which parts are consumed in each cell as the unit runs down the line to be assembled.

after that it would be nice to have a pick list of all the fabricated parts used within the unit for material handlers to set up each job on its cart.

I would really like to hear what others think on the path we are heading and how can we achieve this with the traveler?

Are there better ways we should thinking of?

Thanks for any comments and suggestions.