Hello, New user, mid-implementation. My consultant and I are not 100% sure how the scrap feature works in epicor. My company makes machined components with roughly 1-20 operations in the manufacturing process. In our current MES, we assign a global scrap rate in %. This dictates how many pcs of overrun we will plan for. Example, an order for 100 pcs, but we expect 30% fallout, then we will start the order for 130 pcs. This is not done at the op level, simply a global % based on the part itself. Ideally we could switch to per op scrap rates(data we have) and use that to drive the total overrun quantity. Seemingly the scrap rate as it sits in kinetic just serves to tell us to make more for each op but that does not feedback in any way to the first op or the material requirements. We can trick the system by setting the first op to have the 30% scrap which does give us the overrun we need, but ultimately we would have to set all other op’s scrap rate to 0%. This is not how we want to use the system. Ideally the system would combine the individual scrap rates and give us the correct quantity to start with to make the order. Example, 3 operation part with 5% scrap at each op would net a starting quantity of 1.05 x 1.05 x 1.05=115.8%. Seemingly I just don’t understand the purpose of the native scrap rate. Before building a customization, I wanted to reach out and see if anyone could point me in the right direction. Thanks.

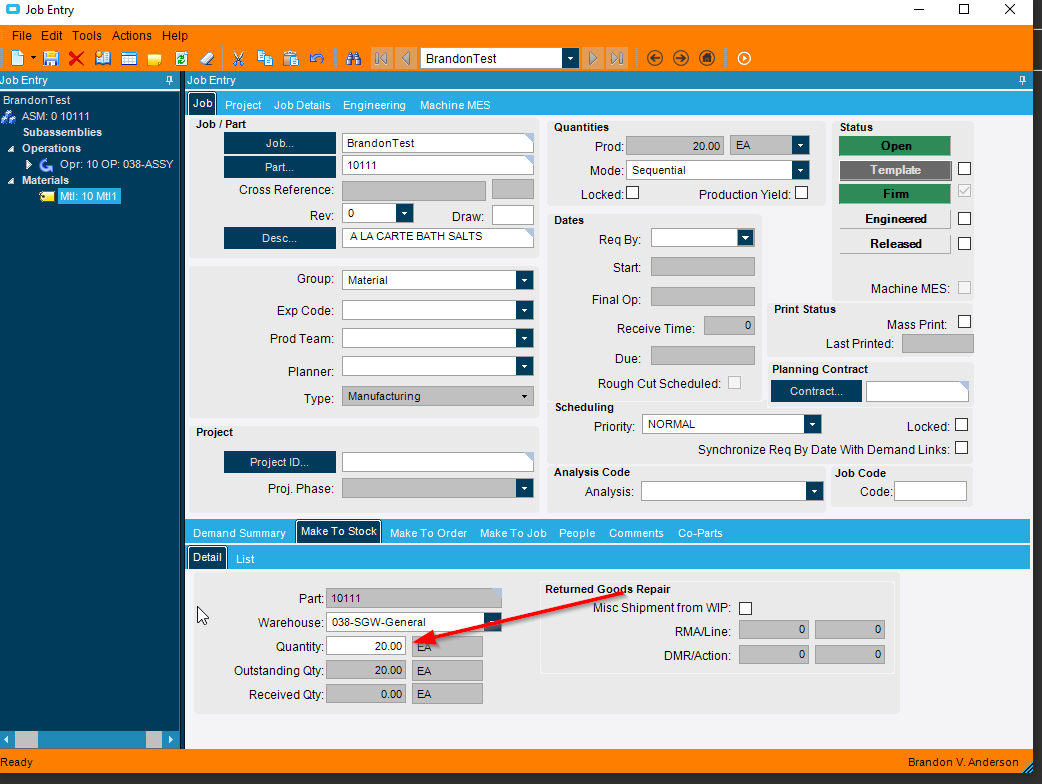

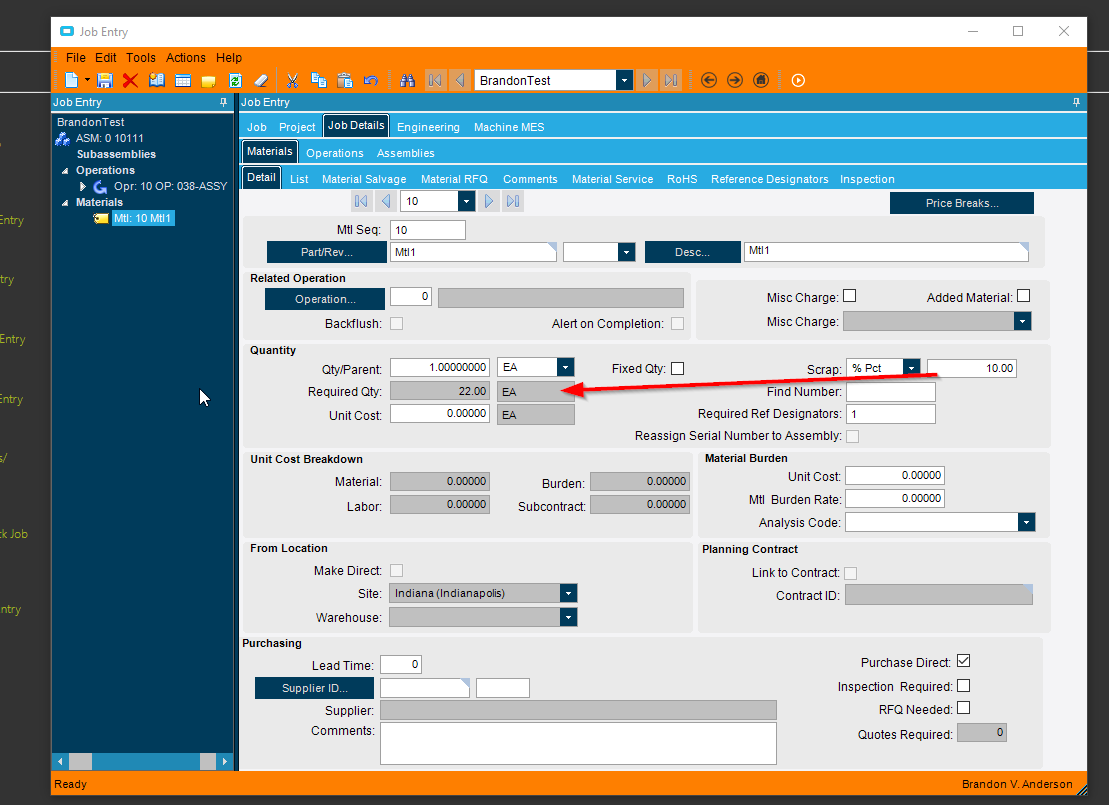

The scrap rates for the material is on the material, not the operation. See the screen shots below for a sample job of 20, with a material at 1 per with a scrap rate of 10% give a required material of 22.

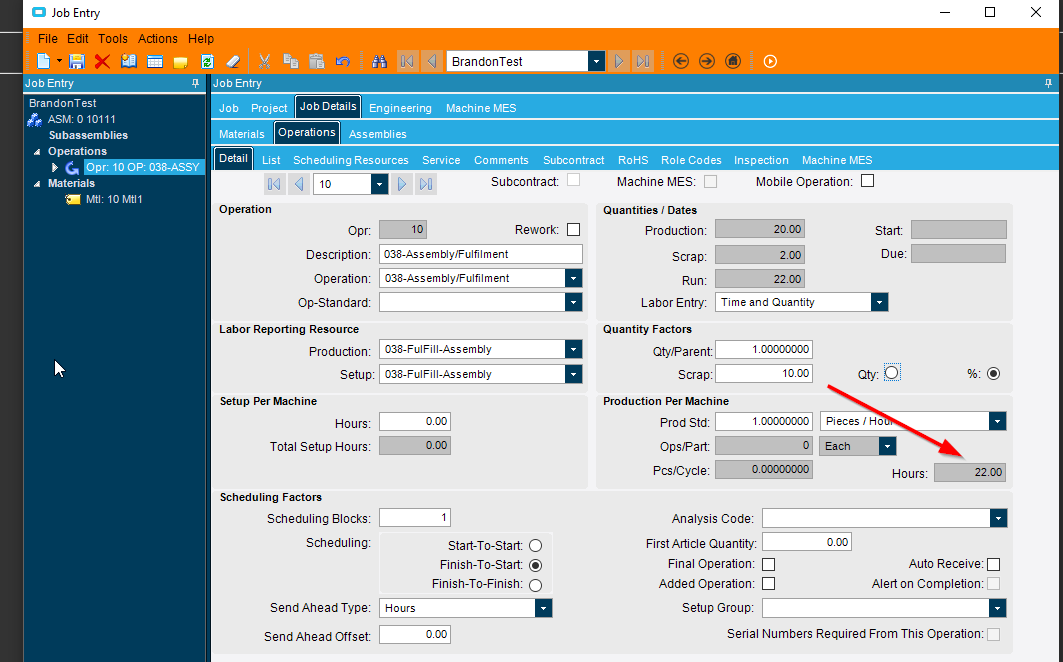

Scrap rates on the operations have to with how much labor is required. So if you add a scrap rate on your operation, it adds it to the labor time (not the material)

These are separated to give to the appropriate control that you need as different industries have different definition of what that scrap would be. For example, if assembly has a scrap rate of 2%, they can probably just take it apart and put it back together again, so there is no wasted material. While a machining operation probably ruins the material. But Epicor can’t know that, so they put you in charge of figuring out the material scrap rate, and the labor time scrap rate separately.

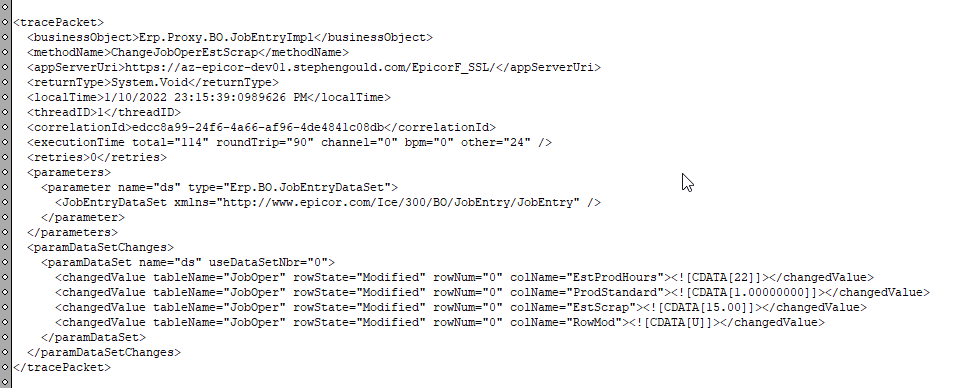

If you want to relate the operation scrap rates to the material scrap rates, a BPM can be make to recalculate the material scrap rate to equal the total of the operation scrap rates if you so desire.

That will go on this method.

Remember whenever trying to figure out what Epicor (or any software for that matter) is doing, keep the perspective that Epicor has to be a jack of all trades and try to fit as many industries as possible. That makes it a master of none, and the trade off to that is it usually doesn’t make 100% for every process in your business because each business has it’s own way of doing things.

Thank you for your input. I just wanted to make sure I wasn’t overlooking something obvious. We will write a BPM to figure this out.

@Banderson , @josecgomez , @bderuvo , @jgiese.wci , or any other admins.

Can you mark Brandon’s response as the answer? This is a very well explained response that needs to be highlighted as correct for anyone else searching the forum.

He’s already abused his own power and done so #Dictator! ![]()

At least I waited until someone asked.

You have to give him credit for that.

Hi - bit of a thread bump.

Whats the best way in Epicor to plan for scrap if the scrap could occur at anyone one of the multiple operations required to produce the part?

Say we have an order for part A, qty 50, and the production method has 10 unique ops each with a material requirement…

We know from past production that every time we make this part, regardless of starting qty, we scrap 2, but the operation causing the scrap is different each time.

Is there a way to get Epicor to add 2 onto the required qty, ie raise a job for 52, so that we yield the required 50

Thanks

Sorry for the double bump but reading through this thread has taught me I was making an incorrect assumption.

I wanted to start having Epicor do the thing @paul_luvaglia is referring to here.

I have a part that has 5 operations, and I can expect a certain amount of predictable loss between each op.

If I want 100 pieces to come out of the final op, how do I tell the first op to make 110 so my final op person has enough material to work with to satisfy all 100?

@hackaphreaka and @paul_luvaglia

We do this but we had to execute this 100% with custom code. Essentially we assign a scrap rate to each op, then back that up to the first op and multiply to arrive at an ‘overrun’ number. All custom code. Found nothing native in Epicor to handle this.