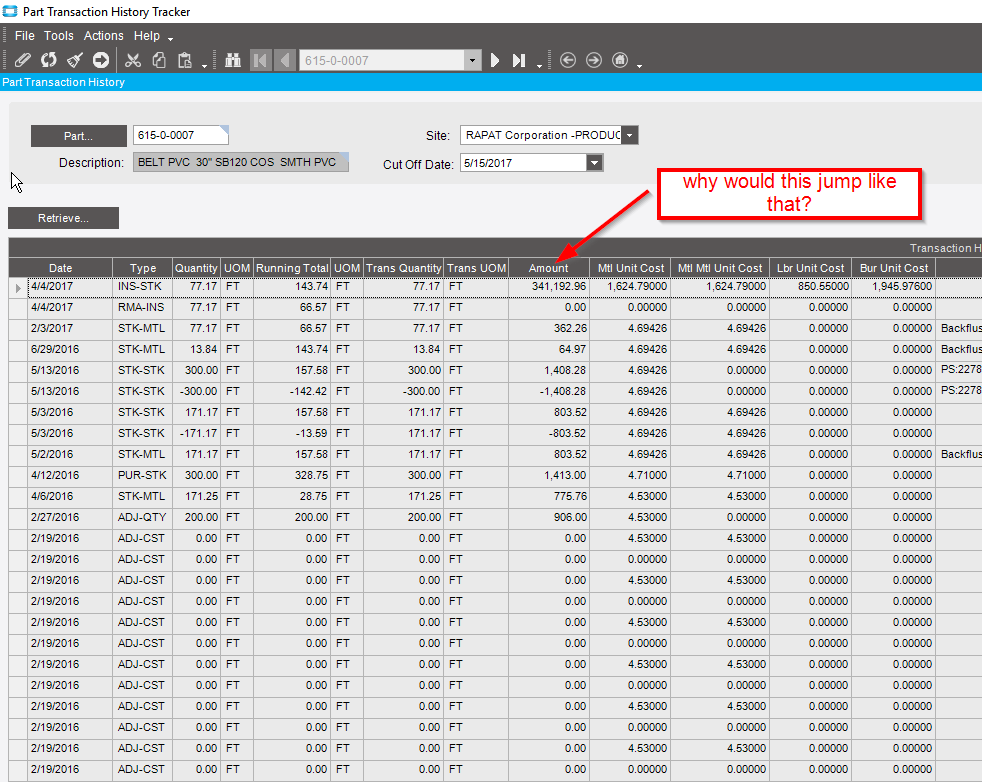

So we have a really weird problem. Somehow in an inspection-stock transaction, this part number pulled in some outrageous costs. This part is purchased a $4.70 a foot and for some reason, this transaction has a 77.17ft belt coming into inventory at a cost of $341,192. Does anyone have any idea where to even look to see what happened on this? Does anyone how to fix the wrong transaction of INS-STK?

I would look at the cost that was given to the material on the RMA and RMA disposition.

Gotcha, it’s in the RMA disposition screen (which I didn’t know existed) Everyone here was telling me that every screen they used to process the RMA didn’t have cost listed. (which obviously isn’t true)

For anyone that is interested, If you are returning something that is part of a line on an order. (this one happened to be a belt that goes on a conveyor) the costs that are associated with the RMA are the cost ON THE WHOLE LINE. Which is incredibly dumb, because if we were returning the whole line, the part number would match what was on the line. When the disposition is done, the cost needs to be overridden to be the cost of the part that you are returning.

Also there seems to be a bug in the system where if the item being returned has a different UOM of the item on the order line. In this case the belt was by the foot, and the order for the conveyor was each. So now it won’t let me save the order disposition with the corrected costs on the belt because the UOM’s don’t match. I have a call with support scheduled to see if they can fix this.

BTW, if you’re doing a repair to customer-owned material, this (RMA Disposition) is the place to set the cost to zero if you’re not taking ownership of the materials but only doing a repair.

Mark W.

Check your part costs. The transaction row is stating over a thousand

dollars for the material and labor fields.

Brad

I have a feeling that you are going to get the response “the system is operating as programmed”. I think the only way you could return a piece of a part would be if the part was a Sales Kit.

The way I would handle this is to return the top level part and put it into a job. In the job add the material that is being replaced and you will be at the lower level.