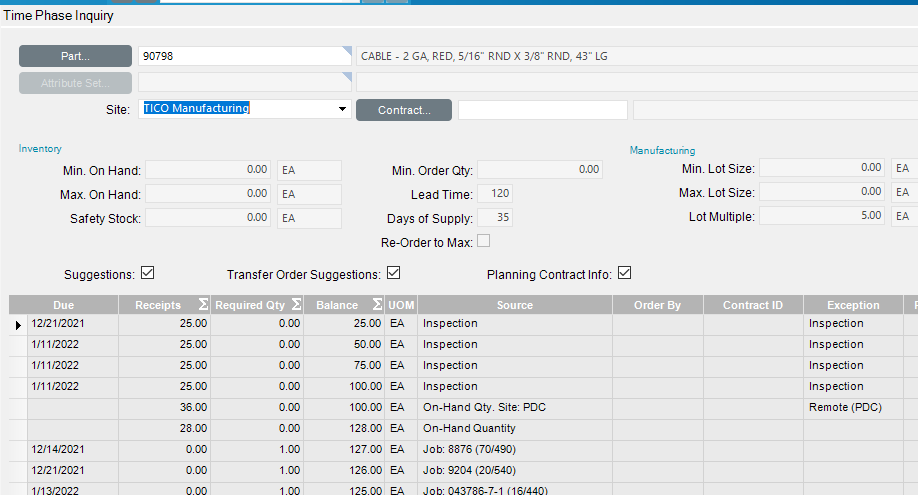

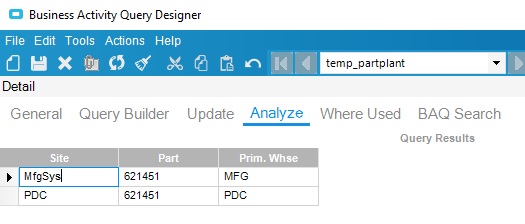

Reason I am asking is that I have a quantity showing in site [blank] which happens to be the total of the other two combined:

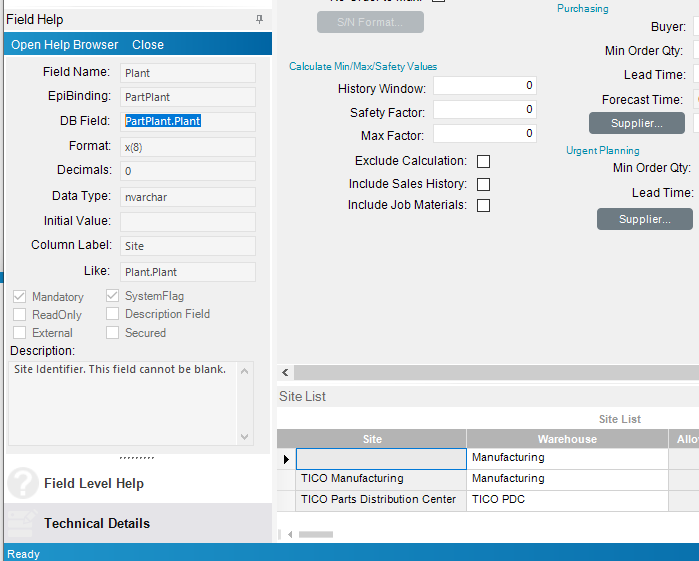

I did have a entry in PlantWhse for this part with a blank site but I, um, made that go away*, and this still persists.

*I don’t want to say what I did ahem but it’s the same thing that this fix from Epicor support did, which gets rid of bogus PlantWhse records:

SQL code from support

-- ---------------------------------------------------------------------------------------------------------

-- <GEN DATE>04/18/2019 11:29:59</GEN DATE>

-- <MODIFIED>NO </MODIFIED>

/* <KNOWLEDGE> */

/* <ShortDescr>

Delete PlantWhse if its Plant and WarehouseCode cannot be found in Warehse

</ShortDescr> */

/* <meta>

Part Tracker, PlantWhse, 17079ESC

</meta> */

/* <Issue>

Duplicated records found under On Hand -> Bins tab in Part Tracker

</Issue> */

/* <WhatSelected>

PlantWhse record if its Plant and WarehouseCode cannot be found in Warehse

</WhatSelected> */

/* <WhatProgramDoes>

Delete PlantWhse for the selected records

</WhatProgramDoes> */

/* </KNOWLEDGE> */

/* <FIX DESCRIPTION> */

/* Delete PlantWhse If WarehouseCode Does Not Exist In Warehse */

/* </FIX DESCRIPTION> */

-- ---------------------------------------------------------------------------------------------------------

DECLARE

@Company nvarchar(max) = '<ALL>' --** allok

, @Plant nvarchar(max) = '<ALL>' --** allok (PlantWhse.Plant)

, @WarehouseCode nvarchar(max) = '<ALL>' --** allok (PlantWhse.WarehouseCode)

, @updind bit = 1 -- 0 = Display Only/ 1 = Display then Update

DECLARE @sysrowid uniqueidentifier

declare @updinfo table (

PlantWhse_Company nvarchar(8),

PlantWhse_Plant nvarchar(8),

PlantWhse_WarehouseCode nvarchar(8),

PlantWhse_PartNum nvarchar(50),

sysrowid uniqueidentifier,

rowid_112233 int identity(1,1))

DECLARE @companyP_company nvarchar(8), @companyP_sysrow uniqueidentifier

DECLARE @PlantWhse_Company nvarchar(8), @PlantWhse_PartNum nvarchar(50), @PlantWhse_Plant

nvarchar(8), @PlantWhse_WarehouseCode nvarchar(8), @PlantWhse_sysrow uniqueidentifier

DECLARE @Warehse_sysrow uniqueidentifier

DECLARE companyP_cursor cursor LOCAL STATIC FORWARD_ONLY READ_ONLY for

select companyP.company, companyP.sysrowid

from Erp.company companyP

join ice.SysCompany s on s.company = companyp.Company -- ds generated Install Link

where (companyP.company = case when @Company = '<ALL>' then companyP.company else @Company end)

order by companyP.company

OPEN companyP_cursor

FETCH NEXT FROM companyP_cursor into @companyP_company, @companyP_sysrow

WHILE @@FETCH_STATUS = 0

BEGIN

DECLARE PlantWhse_cursor cursor LOCAL STATIC FORWARD_ONLY READ_ONLY for

select PlantWhse.Company, PlantWhse.PartNum, PlantWhse.Plant, PlantWhse.WarehouseCode,

PlantWhse.sysrowid

from Erp.PlantWhse PlantWhse

where PlantWhse.company = @companyP_company and (PlantWhse.Plant = case when @Plant = '<ALL>' then PlantWhse.Plant

else @Plant end) and (PlantWhse.WarehouseCode = case when @WarehouseCode = '<ALL>' then PlantWhse.WarehouseCode

else @WarehouseCode end)

OPEN PlantWhse_cursor

FETCH NEXT FROM PlantWhse_cursor into @PlantWhse_Company, @PlantWhse_PartNum, @PlantWhse_Plant,

@PlantWhse_WarehouseCode, @PlantWhse_sysrow

WHILE @@FETCH_STATUS = 0

BEGIN

If NOT Exists (select 1

from Erp.Warehse Warehse

where (Warehse.Company = @PlantWhse_Company and Warehse.WarehouseCode = @PlantWhse_WarehouseCode and

Warehse.Plant = @PlantWhse_Plant))

BEGIN

insert @updinfo (PlantWhse_Company, PlantWhse_Plant, PlantWhse_WarehouseCode,

PlantWhse_PartNum, sysrowid)

select @PlantWhse_Company, @PlantWhse_Plant, @PlantWhse_WarehouseCode,

@PlantWhse_PartNum, @PlantWhse_sysrow

END

FETCH NEXT FROM PlantWhse_cursor into @PlantWhse_Company, @PlantWhse_PartNum,

@PlantWhse_Plant, @PlantWhse_WarehouseCode, @PlantWhse_sysrow

END

CLOSE PlantWhse_cursor;

DEALLOCATE PlantWhse_cursor;

FETCH NEXT FROM companyP_cursor into @companyP_company, @companyP_sysrow

END

CLOSE companyP_cursor;

DEALLOCATE companyP_cursor;

select PlantWhse_Company, PlantWhse_Plant, PlantWhse_WarehouseCode, PlantWhse_PartNum

from @updinfo

order by rowid_112233

-- ---------------------------------------------------------------------------------------------------------

-- Data Update Section - Do Not Remove

-- ---------------------------------------------------------------------------------------------------------

if @updind = 1

begin

DECLARE Upd_cursor cursor LOCAL STATIC FORWARD_ONLY READ_ONLY for

select PlantWhse_Company, PlantWhse_Plant, PlantWhse_WarehouseCode, PlantWhse_PartNum, sysrowid

from @updinfo

order by rowid_112233

OPEN Upd_cursor

FETCH NEXT FROM Upd_cursor into @PlantWhse_Company, @PlantWhse_Plant, @PlantWhse_WarehouseCode,

@PlantWhse_PartNum, @PlantWhse_sysrow

WHILE @@FETCH_STATUS = 0

begin

set @sysrowid = @PlantWhse_sysrow

begin tran

delete from Erp.PlantWhse

where sysrowid = @sysrowid

commit tran

FETCH NEXT FROM Upd_cursor into @PlantWhse_Company, @PlantWhse_Plant,

@PlantWhse_WarehouseCode, @PlantWhse_PartNum, @PlantWhse_sysrow

end

end

It doesn’t really harm anything to have a bogus extra row in time phase, but it does bother me.