Is it necessary to add an operation in a BOM. We do use the “backflush” function and I have been told that if we do use this, then we have to have an operation. But what if there is no backflush material on a BOM, is an operation still necessary?

What is your definition of a BOM? I interpret a BOM to only be a bill of materials with no operations.

Epicor calls what makes up a Job as BOM, BOO (Bill of Operations), and MOM (Method of Manufacturing). Just want to make sure we are talking apples to apples.

Yes, Bill Of Materials, but we add operations and material that are linked to the operation. We are wondering if we need an operation at all. But I was told if we backflush we need one.

I have never actually tried, but it should be an easy quick test for you.

- create a part with a BOM and no operations

- make sure that the materials are marked as backflushed

- create a JOB for that part, and get details

- release the job

- receive the finished parts from the job

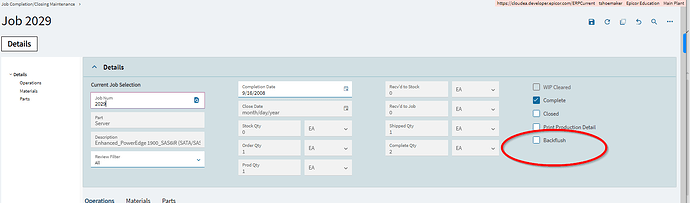

- close the job, and check the backflush checkbox

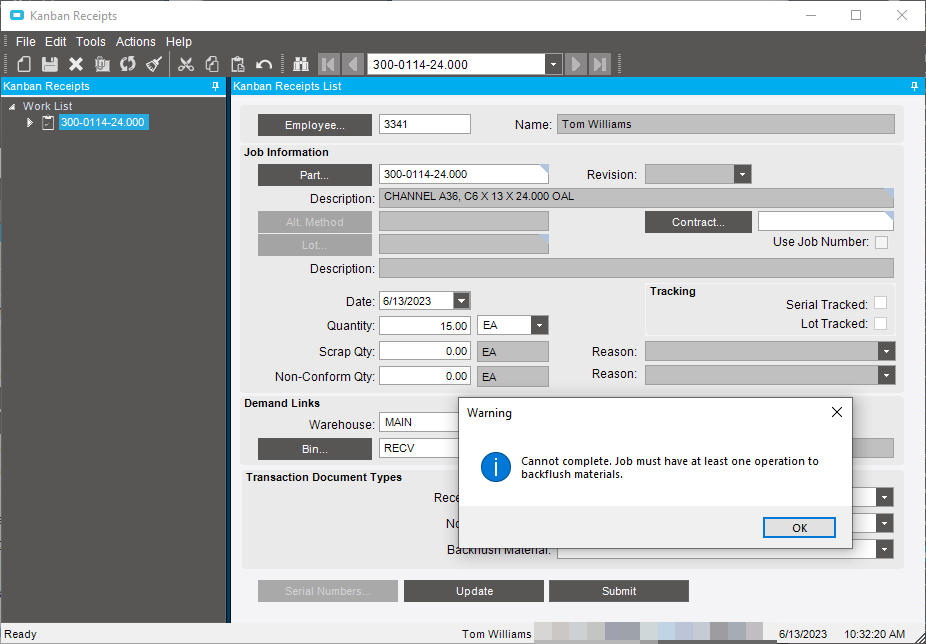

The other option would be to use the KANBAN option… you can do a kanban receipt, which also does “backflushing” but also skips the creation and close steps because they are automatically done for you.

Tim - that’s a good idea! I will try that tomorrow and see what we find. Thanks for the help!

You have to report quantity on an operation for backflush to work. Simply receiving to inventory will not backflush the required parts.

My question would be how do you manufacture something with no operations? You might want to look into Sales Kits if you are just gathering material to ship.

Every material has a related operation. If you do nothing it will default to the first operation in the BOO. The operation the material is related to is directly tied to backflushing. Reporting quantity on the related operation in MES will backflush that material, if the material is set to backflush.

This isn’t 100% true. You can have unrelated materials (they will have 0 listed in the related operation)

These won’t backflush.

Also, it will only default the the first operation if there is a first operation to default to when the material is added. So if you add all of your materials first, then add your operation, your materials will have a 0 for the related operation and will not be tied to anything.

They should be related, it makes scheduling and purchasing and a bunch of other things work better, but it’s not explicitly required to be.

Hi Brandon, if there is no material that is backflush in a BOM, do I still have to enter a operation in order for the job to issue, ship, and complete?

No, you can issue materials without an operation, and ship from job and check the complete checkbox.

Some automatic things built into epicor won’t work because it’s expecting the operations, and I would have to track down the costing parts of it to make sure they work correctly, but worst case scenario you would see job variances to catch up any issues when you close the job.

Ok that’s what I was thinking just wanted someone to confirm. I’m going to test some things today and your input should help! Thanks!

@timshuwy Tim, in a May 2021 post, (Simple material backflush question), you said “All materials should always be associated to an operation.” I agree with that. In my past system, one could not save a Job or a Current BoM (MoM in Epicor) without at least one operation. I’m not sure that I can think of a downside to having an operation in a Job/MoM. If it’s a matter of not wanting to take the 15 seconds to drag an operation from the Engineering tab of the Job or Engineering Workbench, created some template parts with the proper operation and duplicate those. There’s an old adage that says “Just because you can, doesn’t mean you should.”.

I don’t mean to sidetrack this post, but I would be interested in hearing from others as to why one should not have at least one operation in a Job/MoM. If met with objection to adding this question to this post, I will post it separately.

FWIW I agree with @Rookie . (and @timshuwy and everyone else…). I don’t understand the need to not have an operation.

But I do get that there are managers out there who want what they want and won’t change their mind for anything.

Technically, you don’t need an operation. You still should, but it’s possible to operate without one.

Kanban jobs might be a slick solution for you though if scheduling isn’t a need. You can simply report the quantity, and all of the materials required get backflushed.

Albeit this is from 10.2.400, but I wasn’t able to process a Kanban Receipt without an operation.

Perhaps Kinetic is less ridged, but in my experience ERP systems tend to get more ridged and defined with newer versions, not less. Embrace the Operation.

Nope… kinetic is not less rigid… you probably just proved the point that you NEED an operation to do KanBan Receipts (I was not sure).

That said, I will ask…

- Why dont you want an operation

- how do you “make” 300-0114-24.000 part without any labor or machine time?

- how would the system schedule the work if it doesn’t know how long it takes?

I do want operations. I believe that every Job/MoM should have at least one operation. I just performed the test to check Brandon’s assertion.above that a Kanban Receipt for a part with no operation in the MoM will backflush material.

Just a mention on Backflushing. There are situations where it will drive inventory -ve even if you it turned off.

From the help

There are exceptions that allows an action to continue even if it results in a negative on hand balance. These exceptions are the following:

- Job backflusing - a resource or a resource group is set up with a backflushing warehouse, bin, and job materials.

- Kanban receipts - a Bill of Material’s component will backflush.

- Job closing - backflushes remaining materials.

I’ll be honest I have not tested these scenarios, but thought is was worth a mention.

You are right, it’s needed for kanban, it’s not required for regular jobs. But I 'm assuming (@mhunt can you pipe in here? ) that the desire for no operations is to remove the necessity for recording labor, (I don’t know why else someone would be so averse to it). Using Kanban jobs eliminates a lot of reporting, so I would think it would be worth adding the operation in there.

That is a true statement @Hally. The reason that they chose to allow those is because it’s a high likelihood of out of order transactions, and since things are happening with no UI to ask what to do in those scenarios, it’s better to record the out of order transaction in hopes that it catches up later. (for example, if you complete the op before the material got around to moving the material to the backflush bin, or for the shipping receiver to complete the PO reciept). It will catch up if all of the transactions are completed. If you stop going negative, you will end up with more on hand than you actually have because you truncated the transaction that would have driven the inventory negative.

Be careful with this one. I’ve seen it do some double issuing when you backflush in job closing. Maybe it’s fixed now, but I’ve been gunshy on using that feature.