Does the standard Stock Status Report include Inactive Parts also? We are seeing negative qty on hand for inactive parts which we believe are showing up also in the report which is throwing off the valuations. Any way to zero out qty on hand for Inactive parts?

You cannot make a part inactive if there is a QOH. Including a “zero QOH” for the situation where Bin A has 10, and Bin B has -10 (which net to zero). You need to have no PartBin records for the part.

SSR is date sensitive. If you had a QOH of -10 on 10/31, and then did a QTY adjust on 11/1 to net it to zero, the part could then be made in active (on 11/1). If you re-ran SSR with a 10/31 date, it would still show the -10.

Now had the QTY adjust been done on 11/1, but with a 10/31 tran date, the SSR (with a 10/31 date0 would now show 0 QOH (or exclude the part if that option is selected)

It must have been done some other way because we are seeing a lot of inactive parts with negative on hand qty. It might have been done through DMT or something else.

I’d use Part Tran History Tracker on some of those parts to see what the real QOH is.

I’m 99.999% sure that a part cannot be Inactive AND have PartBin records.

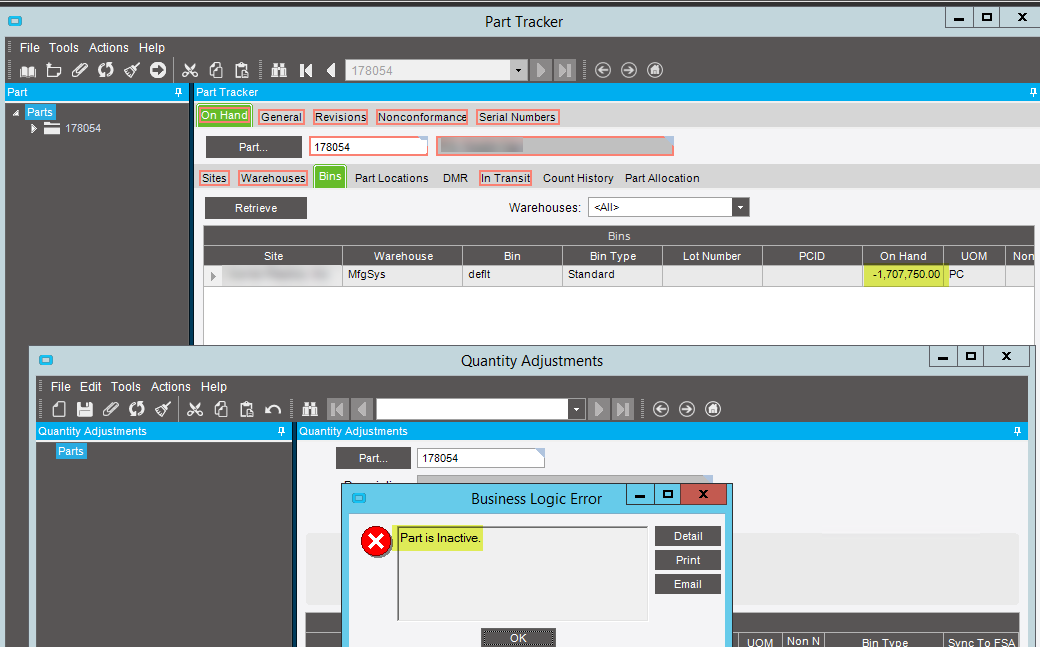

Standard functionality would say yes it cannot be Inactive with PartBin records but we’re not sure how a lot of our Parts are in this scenario with negative on hand qty and are inactive.

Run the “Refresh PartBin QOH From PartTran” process.

It is in:

System Mngmnt -> Rebuild Processes -> Mfg / Distribution

There’s a Report Only option that just does the check, and doesn’t actually update anything. Run that and see if your part 178054 shows up in that list.

Edit:

Use Server File Download to fetch the Log file after the process completes. Chose Directory Type = Company, Look in Log\<your user ID>

Yes, the Part is listed. We ran the update but believe it did not update it. Isn’t that rebuild process the same as the FX_FixBinsAllNew.df fix?

I don’t know about that.

But you might need to temporarily make the part Active for the “Refresh PartBin QOH From PartTran” to work. If after the process runs, and there is a QOH, you’ll need to use Qty Adjust to get that back to zero before you can return the part to being Inactive.

BTW - the “Refresh PartBin QOH From PartTran” will let you pick specific parts, so you don’t have to run it for all parts. Just use the Filter tab

Sometimes strange transactions happen. We have a lot controlled part with a quantity on hand as 100 without a lot number and a negative -100 with a lot number. No idea how a transaction without the lot number got in.

Vinay Kamboj

I believe the discrepancy happened after running the Refresh part quantities and allocations where it removed the negative qty on hand in the warehouse but did not remove it from the bin negative on hand qty.

On your example there, look at Part Tran History Tracker for that Part - find an entry with no Lot Number, and then look to the transaction immediately before it.