Is anybody having to deal with California’s “Safe Drinking Water and Toxic Enforcement Act” (Prop 65) changes coming down the pipe? Is there anything in Epicor (some screen in Part Entry? RoHS maybe?) that can be useful if you want to start doing some label auto-printing or something like that.

Or just do what a lot of people do. That is to include a basic Prop 65 warning insert with every product, regardless if it contains any specific materials.

And I’m not joking. Unless your marketing people scream that sales will drop (which they won’t - the sales dropping), just add it to everything.

I got an external harddrive, and it came with a Prop 65 insert, suggesting to wash my hands after handling it.

Everything You ever wanted to know about the Prop 65 warning requirements:

Calvin,

That would work prior to 2018. Perhaps you have not heard of the new rules added to Prop 65 now:

https://www.exponent.com/knowledge/alerts/2017/08/prop-65-changes/?pageSize=NaN&pageNum=0&loadAllByPageSize=true

Read it, and then go to your sales department and try to convince them that you no longer wish to do business in or around California. ![]()

Ed,

Thanks, we’ve actually been getting a pretty good education on what is required for Prop 65 now. Probably the questions I’m really driving at are:

- Is Epicor doing anything (something in a newer version - we are on 10.1.500 - or something on the roadmap) about all these changes coming to Prop 65 laws?

- Has anybody else already thought of a good way to use UD field or UD tables or something to handle needing to keep a list of what chemicals are listed for each part and what warnings to display? (Does California think it will kill your sperm, kill you with cancer, or both!?)

We’re envisioning now a system where when you ship a part in Epicor, it would look at something on or related to the part that lists out what chemical(s) you are required to show on the warning, and which warning(s) you are required to display, and then auto prints a label.

On this topic of regulatory documentation, has any one addressed Conflict Minerals in their ERP system?

Calvin - I haven’t within Epicor, but we did it outside the system at my last employer. We started by analyzing all the raw material specs (AMS specs), and seeing which of the material specs included the 3T’s + G as required elements (not just 0-2.5% allowed, but just those that had a minimum % required). Then for those, we’d contact the material vendors, who’d provide a blanket “to the best of our ability” statement for the supply chain.

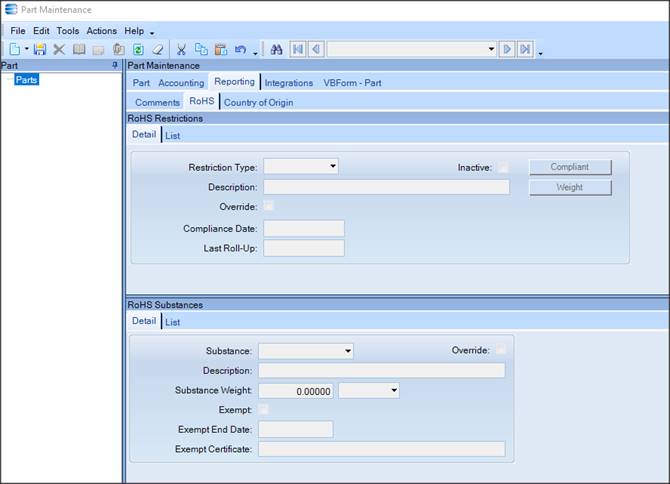

The RoHS module adds restricted Substances to Parts, it would be a good place to start tracking these items.

@Noffie did you end up deploying a solution to help with Prop 65? Our CAM mentioned Epicor didn’t offer anything specific for the need. We bought RoHS as a starting point and planned on UD fields within Part Substance to fill the gap, but its not really ideal.

Sorry, we have not yet. I guess this Rohs idea sounds interesting. Otherwise it sounds like you might be looking at home grown solution, or UD Tables.

From our testing RoHS will be helpful with new manufactured parts, but not so much with existing parts. We see a good amount of part updating with added UD fields in PartRestriction and PartSubstance. We do not have the DMT tool, but may look into it to help update parts.

![]()

That’s like not having a TV. Yeah, you can live without it, but why? Seriously though, it’s super helpful. I don’t know how we would do business without it.